As an Amazon Associate I earn from qualifying purchases through links from this site. See the disclosure page for details.

Recently I heard underwaterwelding is crazy dangerous but insane profitable. So I wondered, why is it? And how does underwater welding really work?

Thus I did an internet recherche and summarized everything I found right here for you guys. See the table of contents below.

Is it even possible to weld underwater?

Well, the very concept of underwater welding may be as baffling as it is dangerous.

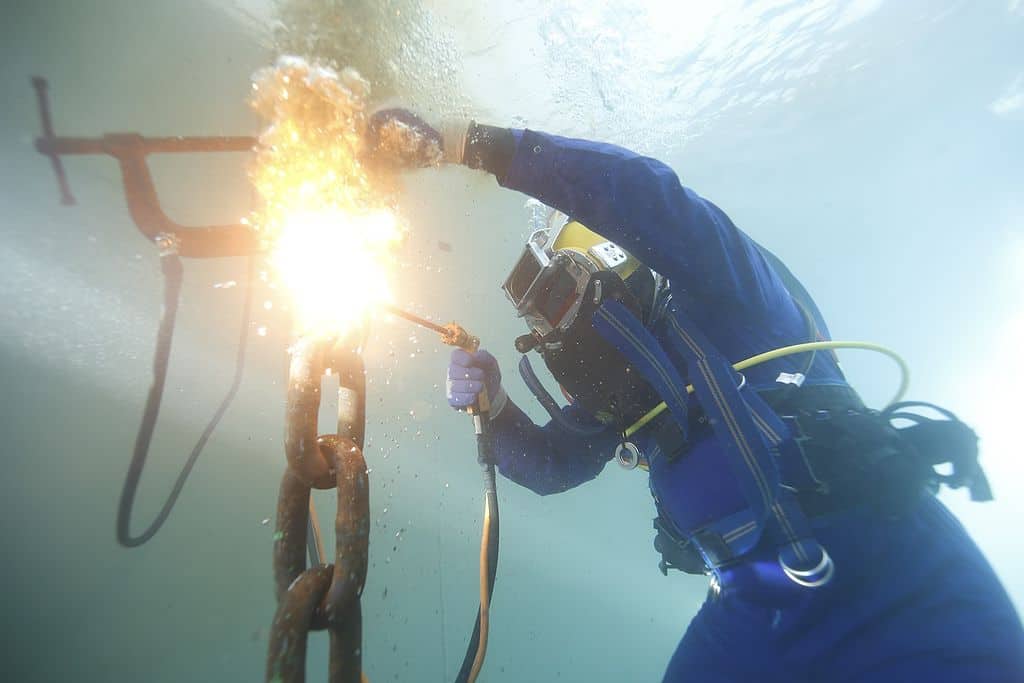

You may wonder how it could be possible to operate a fire underwater, but somehow commercial underwater welders often pull it off wherever necessary.

In spite of the inherent risks of this kind of welding, it’s usually inevitable to repair marine vessels such as ships and ferries which you can’t possibly pull ashore to carry out maintenance practices.

by שאול עומר דוברות חיל הים (שאול עומר דוברות חיל הים) [CC BY-SA 3.0], via Wikimedia Commons

The invention of underwater welding

Konstantin Khrenov, a Russian metallurgist, invented underwater welding in 1932. [Source: Wikipedia]

This discovery came as a solution to the repair and maintenance of marine vessels without necessarily pulling them inshore. It involves installing structures underwater, repair and maintenance of ships, pipelines, locks, and dams. You need to read on to find out more information about this astounding subject.

back to menu ↑Underwater welding methods

Commercial welders use two methods to weld underwater : wet welding and dry welding (also called hyperbaric welding).

Wet welding

In wet welding, the welder directly fixes the workpiece in water using a welding rod different to standard surface welding. Welding under the water requires waterproof electrodes, ranging from 20 A up to 400 amps of power.

The welder dives into the ocean at high barometric pressures with oxygen supplier breathing package as well as the welding equipment, and exchanges command with an operator on the surface.

Welders explore the options of metal arc welding, flux-core arc welding or friction welding. The welder uses the electric arc to heat a welding rod and the workpiece. The gas bubble at the arc transfers molten metal into the workpiece as the current flows.

Dry welding

Dry welding or hyperbaric welding, on the other hand, happens in a dry environment created around the surface to weld but still underwater. The welder seals a chamber in the workplace to create a hyperbaric sphere and fills it with a mixture of helium and argon to expel water.

The ground crew has to ensure proper aeration continually by pumping t in the fresh air and discharging the exhausted air. They also regulate air pressure for safe breathing.

Equipment needed for underwater welding jobs

Similar to conventional welding tasks on land you will need a good welding machine and more equipment to do a solid job:

• Welding machine: to supply constant and stable DC power during welding (Also read: best MIG welders)

• Waterproof electrodes: provides the weld for sealing the metal

• Stinger: plastic that holds electrodes. It should be light, insulated and correctly angled

• Knife switch: a special lever that controls how electricity flows to the welding tools

Of course, before you start to weld with your normal diving equipment you should rethink it.

This is not a suitable underwater welding equipment.

Attire and accessories

Additionally you will need accessoires and tools to make a good welding job. These accessoires can include knives, a helmet, your diving suit, good welding gloves and a umbilical cord:

• Diving helmet: it protects the head, the eyes and the face of the welder; and allows breathing. The helmets vary in type according to work. They include reclaiming, open circuit and free-flow helmets

• Harness: keeps the welder buoyant and confined to the work point without swerving

• Diving knife: has multipurpose use- cutting welding materials and for any safety eventuality

• The gas panel and compressor: supplies and monitors the level of the surface supplied air (SSA) for the welder

• Umbilical cord: the point at which the welder accesses the air for breathing from the surface

• Bailout gas: this is a supplementary gas supply in case the SSA cylinders fail

• Diving suit: waterproof to cover the entire body and prevent water entry

• Gloves with a rubber band snapped around the wrist to protect the hands

Job opportunities

What type of jobs are there?

Typical jobs include inspection and repairing of watercraft propellers and hulls. Moreover you will create underwater constructions of harbor facilities. Installation and repair of pipes is also very typical.

Typical tasks:

- Repair of water vehicles

- Bridge inspection

- Pipe construction

- Non destructive testing of weld seam underwater

- Construction of harbor facilities

- Annual dock inspection

What skills are usually required for an underwater welding job?

- Inspection skills

- Stay calm in stressful situations

- Work with tools

- Experience is a must very often

Where to find a good welding job?

Companies that deal with marine vessels and underwater infrastructure employ underwater welders. The firms include for example Great Lakes Diving and Salvage, Oceaneering International, Ballard Marine Construction, and Alaska Mobile Welding Diving and Salvage.

The jobs involve repairing ships, fixing bridge pillars and pipelines.

Check out the job search engine Indeed.com for more job opportunities on underwater welding.

How much do these welders earn?

Owing to the risks associated with this job, employers make wet welding occupation lucrative by offering huge salaries to their employees.

The average pay for underwater welders is $54,000 annually and $26 for every hour. Most divers earn between $25,000 to $80,000 per year.

Factors such as experience, depth of the work site, type of work and overtime determine the level of earnings for a welder. A professional welder undergoes thorough practical training and obtains the requisite certification to start practicing.

Veteran and experienced welders do even make $120,000 and more.

Read here more about average welder salaries or take a look at my article about underwater welder salaries.

back to menu ↑How to become an underwater welder?

Of course, before you can start underwater welding you have to attend a school to learn it.

Aspiring welders may join the CDA Technical Institute, an accredited school that trains underwater welders in the US.

The Institute falls under the aegis of Capt.Ray Black, a renown international welder, who imparts his expertise to trainees. Black provides services to marine vessels across the coasts of all continents.

Other underwater welding schools we found include Divers Institute of Technology (Washington), Divers Academy International (New Jersey) and International Diving Institute (South Carolina).

Students in generally learn other necessary subordinate skills which include safe diving and how to operate submarine equipment.

Risks and dangers during underwater welding

Underwater welders continuously face the prospect of premature death through electrocution and inexperience.

Researchers present a mortality rate figure of 5/3000 welders annually. Welders barely go beyond 15 years in this occupation. Therefore, no matter the protective measures taken, the risk of death remains high.

A minor breach allowing water-electricity interaction culminates in fatality before the rescue team comes on board. If you prefer to stay outside the water you may also learn how to MIG weld.

Welding risks

• Possible electrocution especially in wet welding

• Decompression sickness because of high pressure of oxygen for breathing

• Drowning due to pressure differentials in water

• Musculoskeletal condition

back to menu ↑What depth of water is appropriate?

Practically, the works occur most of the times at depths less than 50 feet. However, researchers are exploring the possibility of extending the depth to over 3000 feet. The deeper the site, the more the skills and technology required but that does not limit the welder.

Dry hyperbaric welding is currently limited to roughly 1300 ft.

Generally, welding in the sea is easier than in freshwater lakes because the high salt concentration enhances conduction of electricity.

back to menu ↑What type of steels can be welded underwater?

Steels with carbon equivalent < 0,4 %

Steels with less than 0,1 % carbon or less than 0,4% of carbon equivalent can be welded underwater.

Steels with carbon equivalent > 0,4 %

Steels with a carbon equivalent higher than 0,4% can cause hydrogen induced cold cracking.

To weld these types of steel you need to be cautious and use special filler materials or techniques. These techniques can include pre-heating at dry underwater welding or electrode oscillation at wet welding.

back to menu ↑Tips and tricks for successful welding

Preparation is already half the job. We collected several tips and tricks for you.

- Do a good research before deciding to start a career in underwater-welding

- Always conduct a job-safety analysis before taking on any project

- Never use AC power for welding underwater

- Wear the full protective gear before diving into the work site

- Once you land into the water first clear a spot and position the ground clamp in front of you

- Ensure you use the welding torch with the flash arrestor for safety

- Test the welding equipment at the work point before the actual task

- Avoid cutting non-ferrous metals because they don’t oxidize and may lead to an explosion

- Avoid speeding up cutting metal; this may limit the possibility of an inferno

- You should be fully submerged when welding to avoid an electric shock

- Consider keeping a record of the entire welding project for future reference

You may also read: American Welding Society AWS: A Guide to Starting an Underwater Welding Career

Underwater welding – pros and cons

• Good remuneration

• Welding under the water saves costs of docking sea vessels on the land for the otherwise repair exercise

• You quickly access the spot to weld

• Dry welding boosts safety of the welder

• The surface operator monitors the work during dry welding

• High risk of death and short service span in the career

• Need to be physical fit

• Bubbles of water blur the working environment

• Unfavorable weather limits the working season in a year

• To earn much you won’t be at home a lot

• There is a high turnover rate and over 50% do not re-apply for certifcations after 2 years in the job.

Conclusion on underwater welding

Welding underwater is a unique occupation but a very daunting task that requires the expert to use appropriate equipment and attire for the job. Marine companies offer employment opportunities to the trained personnel. Many institutions offer courses in welding, and the salary scale is attractive if you can look beyond the risks.

Welding under the water poses a lot of challenges to expect and impending fatality if the welder messes up or the gadgets malfunction.

All in all, it is important to be enlightened well on the guidelines and precautions to take before engaging in a welding project underwater.

Image Credits: By שאול עומר דוברות חיל הים (שאול עומר דוברות חיל הים) [CC BY-SA 3.0 (https://creativecommons.org/licenses/by-sa/3.0)], via Wikimedia Commons, Pixabay, Pixabay, Pixabay

Amazon.com

Amazon.com